YOUR BEST FRIEND

You can always count on him.

Opportunities of automation for medium-sized companies

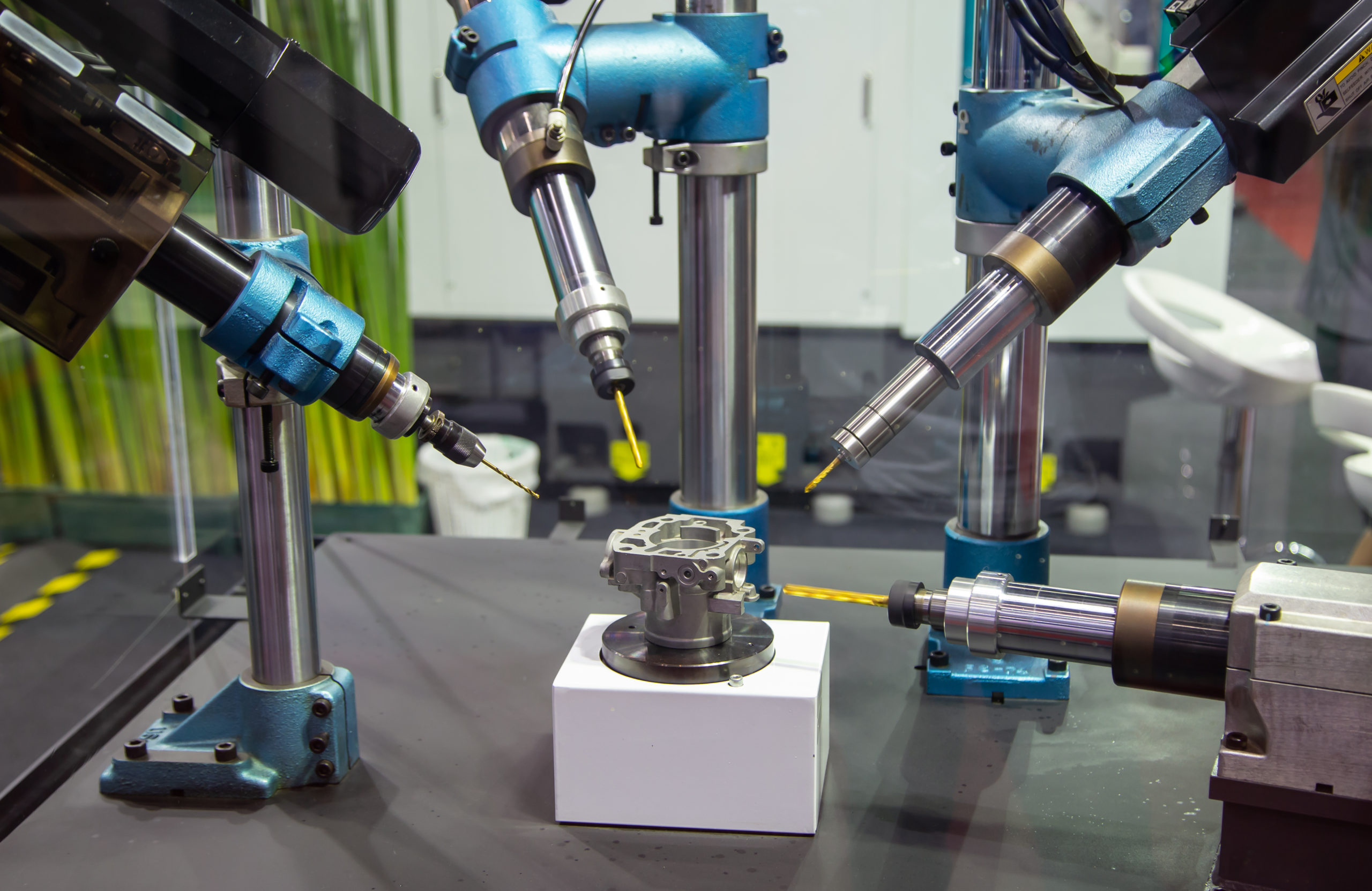

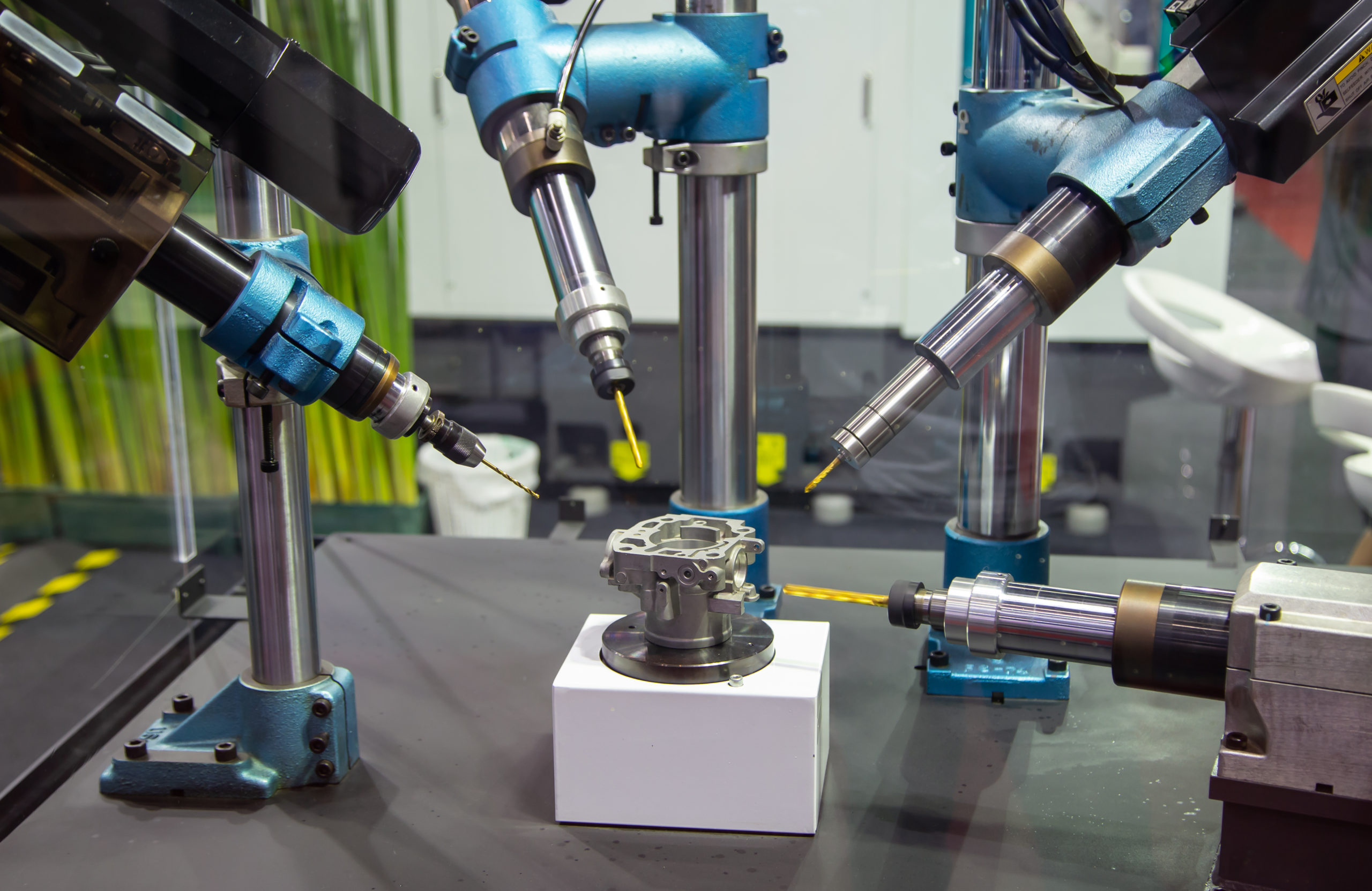

The automotive industry and its suppliers have been doing it for decades. Not only have you integrated your robot colleagues into the process organization, you have also automated entire production lines. The result: higher output, consistent quality and higher added value. Thanks to the robot colleague, skilled workers are spared from dangerous, strenuous and also monotonous activities. They can now use their skills and experience where the robot has its limits.

Away from factory automation towards Germany’s workshops for medium-sized companies. Increasingly, gripping arms of feeding and removing robots and autonomous transport robots are seen here. They work around the clock with consistent quality. As a rule, a smart solution – human-robot collaboration (MRK) – is implemented. Skilled workers and their new colleague, the robot, work together and also share the work.

Typical fields of application for HRC are:

- Assisting support for people to improve work ergonomics.

- Fields of application are mainly found in industrial production, e.g. B. in assembly or handling.

- Workpiece feeding and removal on processing machines to extend operating times at weekends or at night

- Flexible scalability of the degree of automation in production

Opportunities of automation for medium-sized companies

The automotive industry and its suppliers have been doing it for decades. Not only have you integrated your robot colleagues into the process organization, you have also automated entire production lines. The result: higher output, consistent quality and higher added value. Thanks to the robot colleague, skilled workers are spared from dangerous, strenuous and also monotonous activities. They can now use their skills and experience where the robot has its limits.

Our workshops: Hands-on practice

DIEP-Technology would like to promote automation with robots in its constant activity. It is important to generate and convey enthusiasm and understanding. We like to take a pragmatic approach and look for topics from the immediate environment of the employees. Cycle time and processes are critically questioned and analyzed. The goals are to increase or improve productivity and ultimately profitability.

more

Away from factory automation towards Germany’s workshops for medium-sized companies. Increasingly, gripping arms of feeding and removing robots and autonomous transport robots are seen here. They work around the clock with consistent quality. As a rule, a smart solution – human-robot collaboration (MRK) – is implemented. Skilled workers and their new colleague, the robot, work together and also share the work.

Typical fields of application for HRC are:

- Assisting support for people to improve work ergonomics.

- Fields of application are mainly found in industrial production, e.g. B. in assembly or handling.

- Workpiece feeding and removal on processing machines to extend operating times at weekends or at night

- Flexible scalability of the degree of automation in production

The use of robots is also a challenge

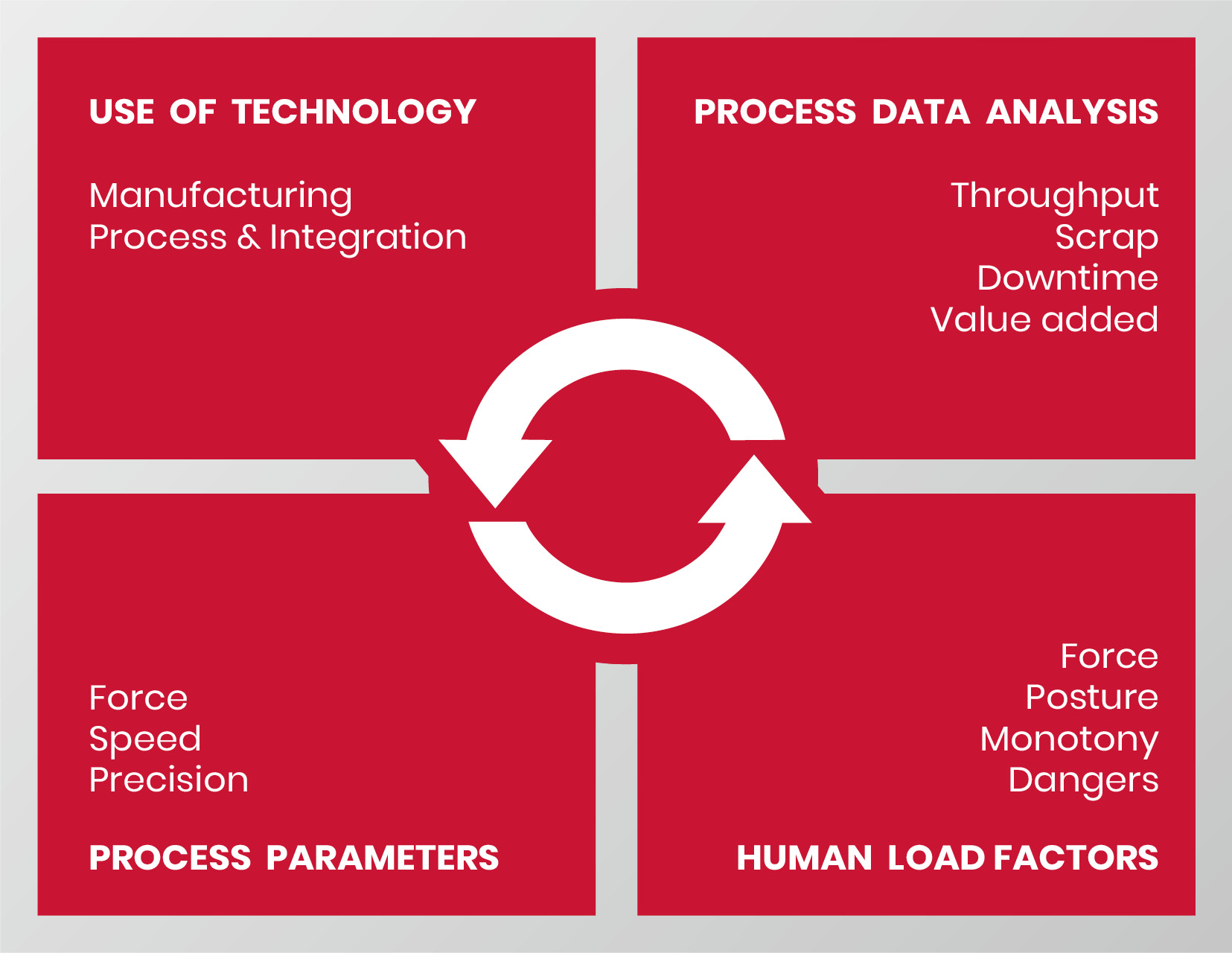

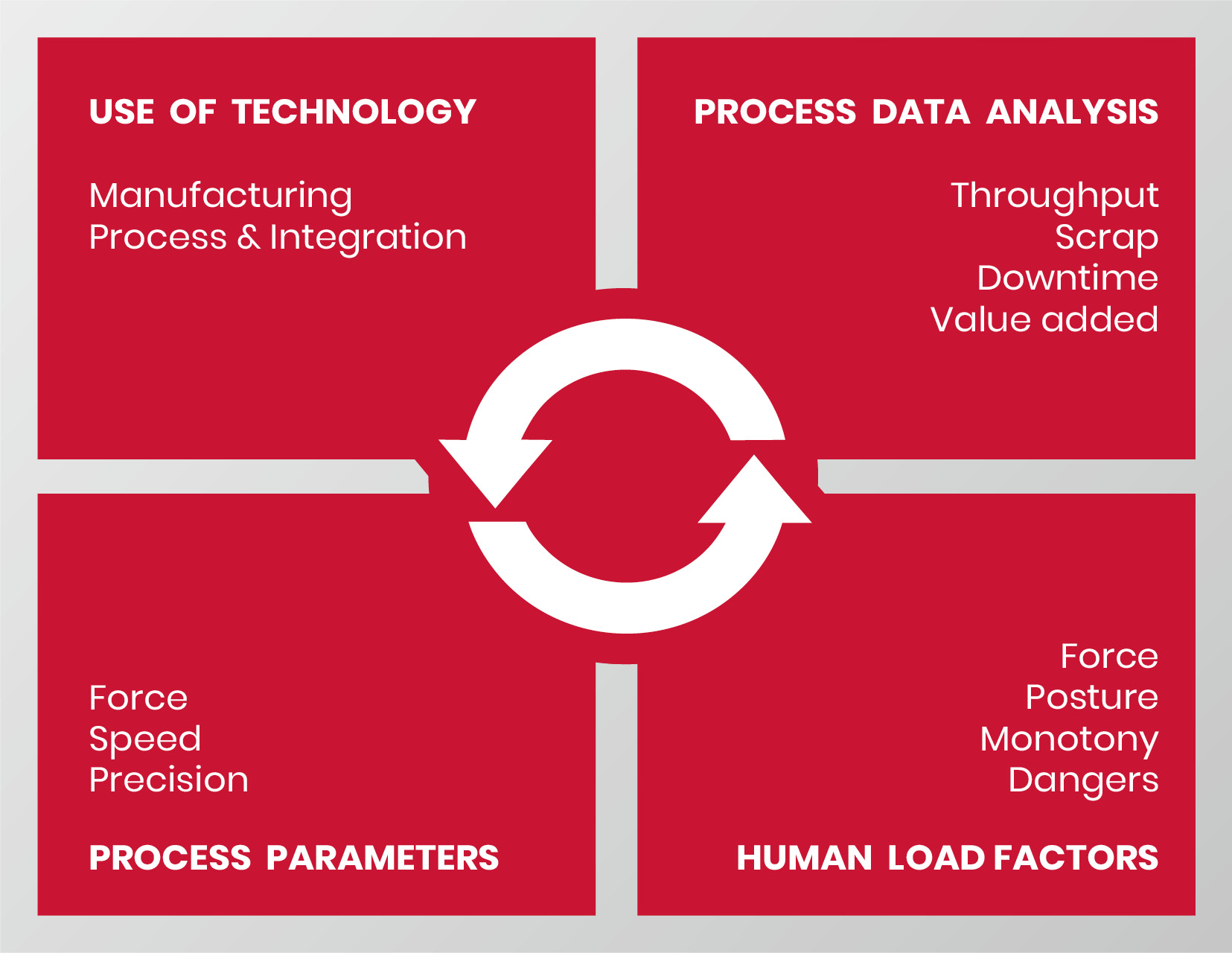

The basic idea behind human-robot collaboration (HRC) is the sensible distribution of work steps between skilled workers and robots within a shared workspace. The strengths and weaknesses of the respective actor (human or robot) are taken into account in order to use the joint potential.

In order to use robots profitably in production, a detailed analysis is required beforehand. examined DIEP-Technology the following topics very precisely:

more

- the manufacturing technology used

- the operational key figure evaluations (KPI) of production

- the burden on employees

- the effects of the individual process steps

These thematic complexes are interrelated, so that an intervention in these processes with the aim of optimization always requires holistic considerations and implementation.

In addition, the prerequisites for the necessary infrastructure must be checked, employee training must be carried out, legal framework conditions must be checked, etc.

The use of robots is also a challenge

The basic idea behind human-robot collaboration (HRC) is the sensible distribution of work steps between skilled workers and robots within a shared workspace. The strengths and weaknesses of the respective actor (human or robot) are taken into account in order to use the joint potential.

In order to use robots profitably in production, a detailed analysis is required beforehand. examined DIEP-Technology the following topics very precisely:

- the manufacturing technology used

- the operational key figure evaluations (KPI) of production

- the burden on employees

- the effects of the individual process steps

These thematic complexes are interrelated, so that an intervention in these processes with the aim of optimization always requires holistic considerations and implementation.

In addition, the prerequisites for the necessary infrastructure must be checked, employee training must be carried out, legal framework conditions must be checked, etc.

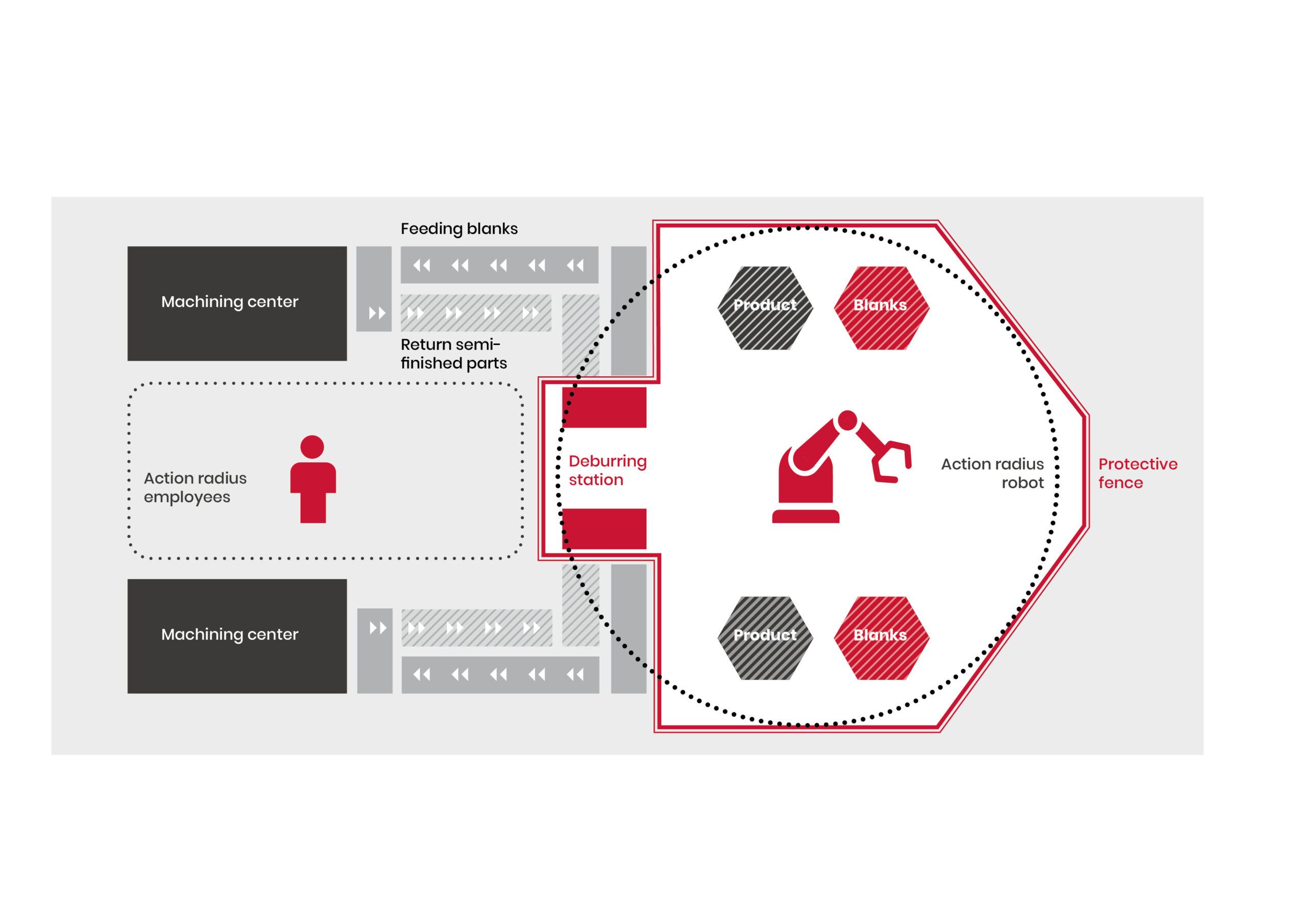

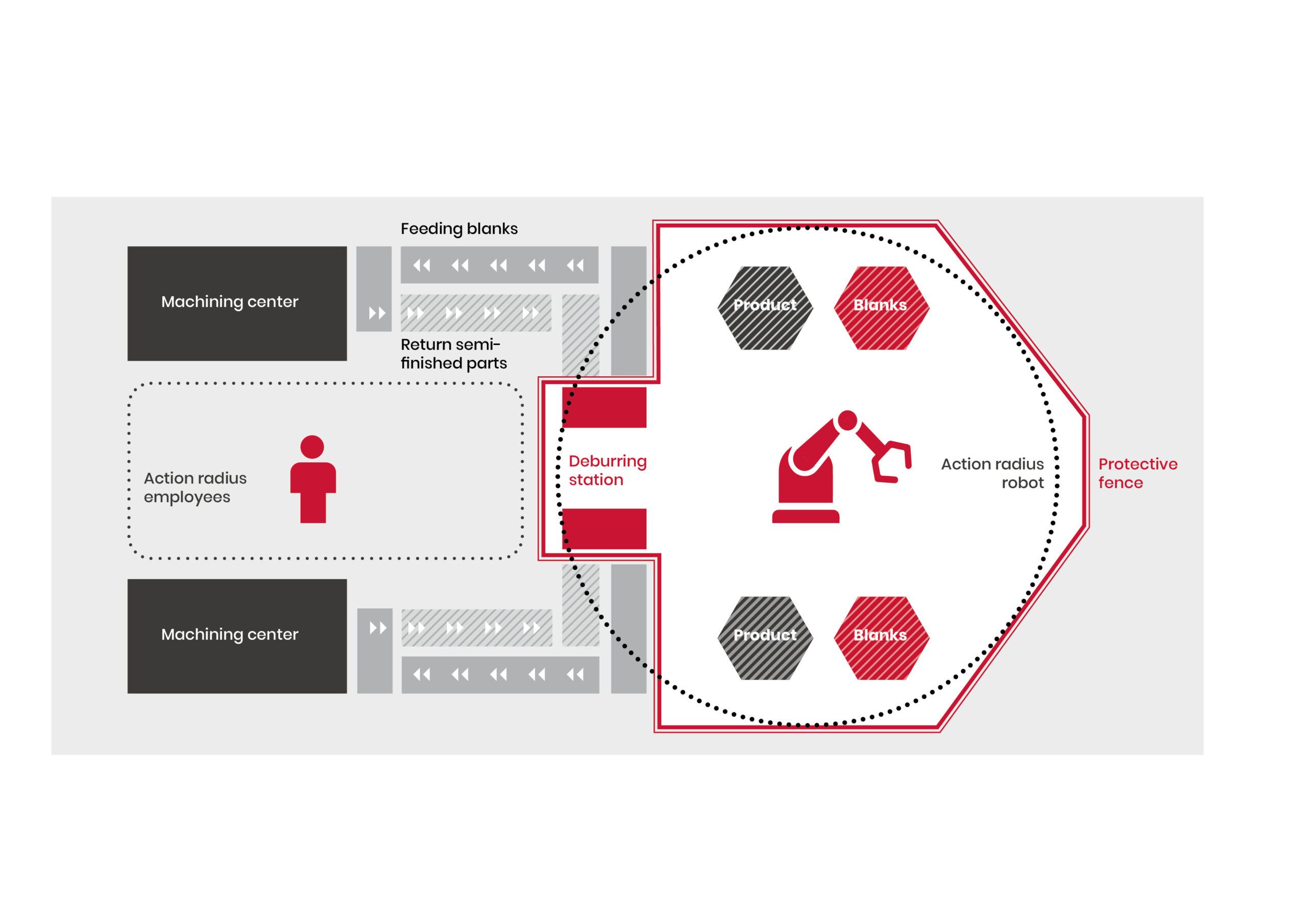

An example from our operational practice:

initial situation

- Medium-sized machining company

- 15 employees

- Very good order situation

- Insufficient staff capacity

Production employees insert blanks into the processing station, remove them again, deburr and pack the finished parts.

more

problem

Ergonomic stress with the consequence of increased sick leave and thus an impairment of performance.

The deburring process is a critical part of the job.

Solution & increase in efficiency

- Robot takes over the deburring

- Robot serves 2 machining centers

- Employees are relieved

- The output is significantly increased (factor 4)

An example from our operational practice:

initial situation

- Medium-sized machining company

- 15 employees

- Very good order situation

- Insufficient staff capacity

Production employees insert blanks into the processing station, remove them again, deburr and pack the finished parts.

problem

Ergonomic stress with the consequence of increased sick leave and thus an impairment of performance.

The deburring process is a critical part of the job.

Solution & increase in efficiency

- Robot takes over the deburring

- Robot serves 2 machining centers

- Employees are relieved

- The output is significantly increased (factor 4)